My

first foray into building a Pz.IV Ausf J was as a dual build. It was an interesting comparison between a mid naughties Dragon kit, considered one of their best Ausf J's releases, and Border Models 2019 released BT-008 kit.

Using the well researched Panzer Tracts No.4-3 publication once more, I would now tackle Ryefield Models (RFM) 2 in 1 kit RM-5033.

This was released at the same time as their interior kit 5043 and uses similar flat pack engineering to create the Wanne (Hull tub). Kit 5033 allows you to build both a gun tank and an artillery observation tank. The instructions have you build the gun tank option with a three return roller Wanne, with extended side towing eyes. This is also how you are instructed to build up the gun tank in kit 5043. However, although not instructed to, you do get the choice to backdate the gun tank in both kits to a slightly earlier production variant, without some of the very last features. All the parts are available on the sprues.

This

is a kit I have very much been looking forward to building. It will be my first RFM kit and I have

only heard goods things about them as a manufacturer. Although I understand purests have spotted some accuracy issues, the kit engineering is much lauded. So without further ado lets get started.

Upon opening

the large box all the sprues are individually packaged and the instruction booklet

looks nice and clear. There is also a small correction sheet, but this looks only applicable to their interor kit 5043. As already mentioned, in addition to the regular Ausf J gun tank, you can also build a Panzerbeobachtungswagen

IV Ausf. J (Pz.Beob.Wg.IV Ausf.J). This was an artillery observation tank which started to

be assembled on the Ausf J in April 1944. This is instructed to be built with a four return roller Wanne. Whether any were built on the later three roller Wanne I am unsure.

Checking over the sprues I was surprised to see a few parts covered in small traces of flash. They don't look too much trouble to clean up, but it is not something I expected to see on a kit so new. There are also a lot of mould stubs on the rear of parts. What RFM can be commended on is the positive placement of many of the more delicately moulded items to the sprue gates. Cleaning them up can be made much easier without sacrificing detail.

RFM offer an upgrade solution for super detailing. Set RM-2003 can be used both on this kit and their interior kit.

A little bit of Ausf J history

The Panzerkampfwagen IV Ausführung J (Sd.Kfz. 161/2) is the ninth and the last variant of the Panzerkampfwagen IV medium tank family. This variant was distinguished by numerous simplifications made to prior variants to accelerate production and conserve valuable materials. This last variant included replacing the single-speed turret traverse electric power drive with a two-gear manual traverse, in favour of extra space used for fuel storage. This was a last-ditch effort to increase Panzer IV production rate and compensate for tank losses.

Although

both Nibelungenwerk (N-Werk from now on 😁) built 2980 units, and Vomag 180 Ausf J's, Vomag did build some of the very first vehicles. Due to the production run timescale the Vomag vehicle chassis numbers (Fahrgestellnummers) 86394 to 86573 would all have had both zimmerit (anti magnetic paste), the original muffler type exhaust and fittings for either type 1 or type 2 steel schurzen (spaced armour). So, due to some other prominent features this kit only represents N-Werk built vehicle variants. N-Werk built vehicles all had a unique application of three spare tracks fittings on the port side of the rear of the Aufbau (upper hull) up until around August 1944 but then switched to a six spare

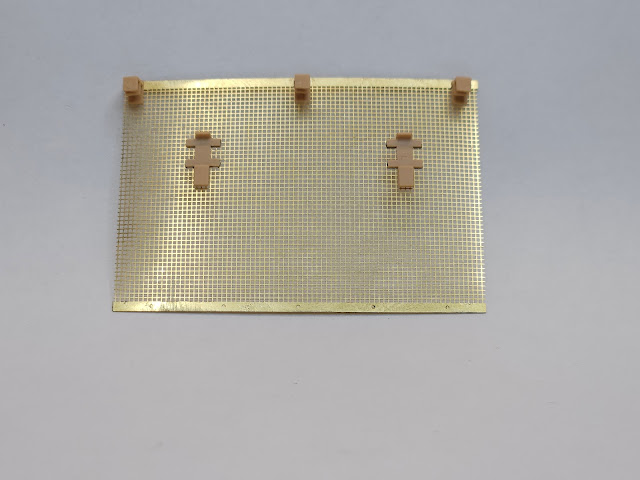

links arrangement on the starboard side. Only Drathgeflechtschurzen (wire mesh spaced

armour) is offered in the kit so that would also mean both variants in the kit could only accurately represent builds produced from Sept 1944 if you decide to add them. Pz.Beob.Wg.IV Ausf.J (artillery observation tank) production started

in April 1944 and although the kit instructs to add the Flammentor (Flame suppressing) twin vertical exhausts (fitted from August 1944), the option to backdate both variants with the older horizontal muffler is possible. The parts are available in the kit but will require additional work, as the location holes on the rear plate are only present for placement of the Flammentor type.

Options on the sprues to backdate both variants.

Options are limited, but as the kit shares sprues from their earlier released Ausf H kit there are a few parts which, although only called out in the instructions to be fitted to the Pz.Beob.Wg variant, could well still be relevant for a late 1944 built N-Werk built gun tank. For the turret, that includes the front plate (part E9) with the vision port still present. This change to delete it was not fully implemented out by wars end. As for Wanne (hull tub) production, the earlier tow coupling (parts K32, K33 & K92) and the later produced Ausf H front sidewall extensions (Parts K56 & K60) without towing eyes, along with rear tow hooks (parts K40 & K41) would have been relevant to all earlier production Ausf J's too.

The Ausf J used a 10./B.W Wanne and RFM offer this in a flat pack engineered design. A nice feature is the ability to open up different holes in the side plates to accept either four return rollers or the last production, bearing material saving three. These were introduced from December 1944. The gun tank option builds up with the last production Wanne feature of front and rear extended sidewalls with towing eyes (from Oct 44). Other late production Ausf J features were the introduction of simple single handles (from Feb 45) These replaced the original cast air intakes on each brake inspection hatch. In December 1944 welded U brackets on the front of the Aufbau started to replace the bolted on lifting hooks. Both options are on the sprues.

The build

After inspecting all the contents and making a

note of what might be available, but not actually called out in the instructions,

I started with step one as per the instructions. As this was RFMs first Pz.IV kit, designed along with their interior kit released later that year, the lower hull is built up in sections to allow for additional interior detail. Any opening hatches come as separate

items which is to be applauded. All

the flatpack lower hull parts erect positively and cleanly and although there is no internal

bracing to fit at this stage it all lines up straight and true. It is worth noting that due to the tight friction design of the sidewall to floor plate connection, some pressure does need to be exerted whilst the glue bonds, to ensure that both pieces sit completely flush along their whole length.

Flatpack 10./B.W Wanne assembled with front towing eye extensions and sprocket housings fitted.

The option to have the main road wheel bogies moveable by

snipping away a small tab is a welcome feature, and all the wheels have poly caps. Pay attention as the idlers use Poly Cap 2 which is shorter. Poly caps when they work; I'm looking at you Border Model, is something I personally like. This system

of wheel fitment is extremely useful if you like to paint your running gear separately. A

design that allows the sprocket to rotate without glue is always a bonus if you have to resort to guiding aftermarket

tracks on, especially where there is limited room below the track guard. Due to snug fitting poly caps both sprocket, idler and roadwheels can all be fixed safely in position without the need for glue.

Moveable bogie suspension

One small anomaly found in this build stage is found on the outer face of the cast idler wheels. They have a small lip on both their inner and outer rim which wasn’t present on the real thing. This will require removal.

The lip present on the right and sanded off on the left. The central greese nipple will need to be replaced if you use a wide sanding stick as I did.

Lower hull assembly with bogies. I have fitted both front and rear extensions with towing eyes and the track pin return plate to represent a 1945 production Ausf J.

The interlocking glacis transmission plate fits snugly between both hull side plates. I did dry fit this to aid spacing before the Wanne assembly fully cured. As mentioned, the option is there to choose either the armoured air intakes or the simple handles on the transmission hatches. Unlike some other manufacturers RFM only provide plastic spare track brackets. These are a little bulky and would be far better represented in photoetch but they are usable. Their spacing is marked out via witness marks on the transmission plate, but they are obviously only for fitment for the RFM spare tracks. If aftermarket tracks are being used, spacing will need to be adjusted accordingly.

Interlocking transmission plate with late production single trans hatch handles fitted

The next steps involve populating both track guards with all the pioneer tools and fittings. You are also instructed to assemble and fit the two part engine cooling louvres. These attach to the track guards before the Aufbau assemby is constructed and added. Again, everything fits extremely well. Unfortunately the C hooks were a bit of a disappointment. They both had two prominent and visible sink holes on one face and will require filler. I simply replaced one from the spares bin. I also sourced a 3D printed empty fire extinguisher holder.

The track guards attach to the Wanne side plates positively due to cut outs, and once in place the engine compartment firewall panel can be slotted down onto the Wanne floor, effectively trapping both track guards in place. This will also provide support for the top plate of the Aufbau once fitted. The Aufbau rear plate can now be fitted.

Flammentor exhaust fixing location detail on the rear plate.

Before committing to final fixing, the Aufbau sub-assembly was test fitted to the Wanne sub-assembly. This locates precisely into slots into both the transmission plate and track guards, and into cut-outs on the rear face of the rear plate. This will then rest on the firewall panel and engine cooling louvres.

Front detail on the Aufbau sub-assembly. The later production feature of square shaped bullet splash guards for both hatches are correctly represented.

Test fitting on my build resulted in the Aufbau top plate sitting a millimetre too high against the rear plate meaning it did not sit flush as it should. The offending items appeared to be both engine cooling louvres sitting a fraction too high. The Aufbau top plate angles down slightly just behind the engine hatches onto the top of the louvres and this is where it was fouling. An armoured outer plate part then covers the top of the louvres and should neatly butt up against both the top and rear plates after the two sub-assemblies are connected. The top plate was also not engaging down onto the firewall, which it obviously should. The only solution was to shave a small amount of material off the top of the louvres.

Slowly removing a little plastic at a time from the top of the engine cooling louvres, the hull top panel finally fell into place. The engine deck hatches, and the remaining fittings could now be added.

With that little fitment conundrum behind me it was time to move onto the turret.

The comprehensive gun breach and cradle parts are exactly the same as on their interior kit. Although not called out, a few other interior items from this kit can be found on various sprue trees. Unfortunately, the rotating turret floor moulding is missing crucial bracket parts that would enable you to add it to the turret surround. However, with what is available, there is still plenty of detail to eyeball, shoud you model any turret hatches open.

It

would have been nice to see a metal barrel although the slide moulded one is

easily cleaned up to remove the very faint seam line. You do get

a choice of three plastic muzzle brakes. As of writing, looking on the Scalemate’s

site, I don’t yet see a metal barrel option available for this kit!

The upper and lower two-part turret mouldings are nicely engineered with weld line detail hiding the joint. The gun breach and cradle fixes to the lower part so you can paint the interior easily enough before joining the turret halves together. Although not called out for on the gun tank option, it would also be appropriate to fit the front panel with the vision port. If the instructions are followed and the vision port delete panel is chosen the four screw head detail moulded onto the turret roof, above and behind where it sat need to be removed.

One small anomaly I found in step 24 was that part S17 (the Nahverteidigungswaffe cover) is orientated in a fixed position on the turret roof. In reality it could rotate 360 degrees from inside the turret so can be fixed in any position. Repositioning it if you wish is simple to remedy. The part has two pips underneath, the larger one is to fit into a 1mm hole that you have been instructed to drill out in step 23. The solution is to snip off the larger pip and simply choose your orientation. The smaller pip sits centrally and the cover hides the 1mm hole that you drilled anyway.

The turret schurzen are accurate for a N-Werk built vehicle in so far as they have the correct brackets and appropriate bolt fixing location points to both the turret and the panels. N-werk vehicles had a unique feature and differed to the earlier Krupp built vehicles. The side plates of the schurzen were mounted 50mm further forward which changed the door position and different support brackets were used. This also meant different mounts held the splash guard protector for the cupola base. The exposed bolt head pattern on the exterior of the front schurzen panel is the visible clue to the manufacturer. The middle bolt will be rearward of the upper and lower bolts on all N-Werk vehicles.

Unfortunately, as soon as I snipped my turret schurzen panels off the sprue gates it was apparent that both the front sections bowed inwards quite badly. I soaked them in warm water and left them overnight under a weight, but they simply sprang back the next day when the weight was removed! I am hoping that the fixing of the brackets to the turret will straighten them out.

As with the hull schurzen the turret brackets were fixed to the panels first to get a nice clean fitment. As there is very little room between both the rear curved panel and the turret bin these areas will require an airbrushed shadow coat before final fixing to the turret. Photoetch storage trays at the rear of the schurzen are added by way of either plastic or PE brackets. As they would be hardly visible, I opted for the more durable plastic option and thinned them down.

The cupola assembly is a comprehensive model in itself. It contains a myriad of parts, but they all fit perfectly, and it looks exquisite once built up. You get two main cupola contruction options; one to build up with the armoured visor covers permanently open, and one so the covers simply slot in and can be left moveable.

Tracks

RFM offer individual links together with a fitting jig. They are an appropriate type for the vehicle. Along with this out of the box solution I had quite a few other options. First up I had the three-return roller link and length tracks leftover from the Border kit. In addition I also had two 3D printed aftermarket sets. T-Rex and QuickTrack. As I hadn't yet tried them, I finally opted for the QuickTrack snap fit set.

These are type 7 links and come in two bags for both left and right fitting. A small bag with a few open links and wire, to which you can thread through to close a completed track loop is also included. Both runs were built up in an alarmingly quick 20mins. They do indeed simply snap together and are far more robust than they look once assembled.

The idler wheel axle does have a small locating tab to fix it in one position inside the lower hull housing but that is easily removed if you wish to adjust it. Even with the tab left in place both my completed runs fitted perfectly. The top run doesn’t sag over the return rollers as naturally as the T-Rex type links with pins, but that is simply due to the QuickTrack design having more friction in the snap nature of the connection. It is not an issue as it only takes a little manual manipulation for them to look the business.

Next up is the Drathgelflechtschurzen (mesh space armour). In these steps you can build the kit up without the tubular rails altogether, by simply adding blanking plates to the upper hull. To replicate this option accurately you would have to drill lots of very small holes in the track guard side profiles where the lower brackets would have attached. That will involve a very fine drill and a very steady hand!

The tubular top rail provided only comes with cut-outs for the mesh panel brackets. There is no complete rail without any cut-outs to provide an alternative empty rail. If you wanted to display the odd mesh panel missing, you would have to fill the cut-outs. I notice RFM in one of their CAD images simple show the brackets attached to the rail where a central mesh panel is missing which is a little strange. In reality the bracket was welded or bolted to the panel and clipped over the rail. The upper brackets connect the tubular rail to the rear of the schurzen panels. The lower brackets connect the rear of the schurzen panel to the track guards. These lower brackets are in two parts to allow for two fitment postitions. This was to enable the use of wider Winterketten/Ostketten tracks. The upper rail brackets is in one part but has two fixed positions whereas the track guard brackets had to be adjusted to sit further out to accept the wider track type. The outer portion of the bracket needs to be positioned horizontally to clear the wider track type. In step 17 these are only shown fitted in the vertical position to accept the regular tracks included in the kit. The real bracket was hinged but you need to decide which perminant option you want beforehand (unless you fancy drilling and pinning all eight brackets!)

The middle mesh panel looks a little out of alignment in the pic below, but that is due to the rails being dry fitted to the hull.

Rather than attaching the tubular rail brackets to the upper hull as instructed, I employed a similar method as I had with a previous Ausf J kit. As the connection point on the bracket requires work to get it to sit cleanly in the tubular rail cut-out, I reckoned it a whole lot easier to get that cleaner connection by attaching the brackets to the rail first. Checking as I cleaned up each bracket that it was the correct fitment to the hull, I ended up with a sub-assembly that I could test fit to both upper hull and track guard, to assure it all aligned correctly. I then dry fitted both rail and bracket assemblies, so they fully cured overnight in exactly the right position.

The mesh panels themselves are in photoetch with predrilled holes to align perfectly to the lower plastic brackets. Plastic is used again to represent the upper brackets. These are as thin as you could possibly expect the mouldings to be without being overly fragile. The PE mesh panel weavepattern looks really good, and they are convincingly thin. The upper brackets attach to shallow cut-outs on the top of the mesh panel so as to align with the cut-outs on the tubular rail. Each panel is framed on the outside, represented by PE strips with bolt head detail. These then line up and are fixed to the outside framework of each panel. TBH most of the work during these steps involves cleaning up all the PE strips as they are very thin and prone to bending.

The two lower plastic brackets fit through the mesh panel precut holes and are fixed to PE locking strips on the outside which is nice and simple to achieve. The last step is to add the upper rail brackets to the top of the panels.

Compared to the Dragon and Border kits I built in an earlier blog, I think RFM have improved on both the engineering and the materials used for these mesh screens. Parts fitment is superb, and the scale appearance looks very convincing.

.jpg)

.jpg)

.jpg)

.jpg)