This is the 2016 ‘2in1’ Bronco kit #CB35214. It was the last release of

a series of sWS variants, that were based on the original Great Wall

Hobby mouldings stretching back to 2009.

The detail is sharp, and the armoured cab thickness is nicely rendered

to scale. Although there is a small degree of mould offset on a few

parts there is no flash and very few pin marks present. It is also nice

to see well thought out sprue gate connections, making removal easier to accomplish cleanly.

The all-plastic sandwich design of the front wheels is most welcome as

is the addition of plastic options to replace some photoetch parts.

Unlike the GWH kits Bronco have included a comprehensively designed

engine and although nothing will be seen if the engine hatches remain

closed it is a nice feature that many modellers will utilise. The tracks

are of the individual link type and although not workable they look to

be of good quality. The Bronco kits also include a host of accessories

that include Jerry cans and fuel drums.

The Schwerer Wehrmachtschlepper (sWS; "Heavy Military Tractor") was a

German World War II half-track vehicle used in various roles between

1943 and 1945. The unarmoured models were used as supply vehicles and as

tractors to haul artillery. Armoured versions mounted anti-aircraft

guns or a 10-barrel rocket launcher (Nebelwerfer). Fewer than a thousand

were built before the end of the war, but production continued after

the war of an improved model in the Tatra plant in Czechoslovakia.

There are a few restored armoured vehicle images out there, but they do

appear to have undergone a restoration and are not

always authentically carried out. They are nevertheless a good general

source of information.

Most of the original Great Wall Hobby variants released were actual produced vehicles, but no photographic evidence exists that either the armoured searchlight (UHU) or the armoured cargo version was ever built. Also, although images do exist of the 2cm Flakvierling 38 fitted to both armoured and unarmoured sWS's, it was never acknowledged as an official production type. Although there is a period image of a sWS Flak 36 by the time the sWS was in production the 3.7cm Flak 43 was considered the more appropriate weapon.

This kit gives you options to build a supply ammo or armoured cargo version. I decided to build the produced supply ammo version and used the Nuts & Bolts 41: Bussings schwerer Wehrmachtschlepper (sWS) and Variants as a reference guide. This book has a nice feature clearly showing all the design changes from prototype to production series by way of colour coded CAD scale images.

Whilst there are many photographs of the armoured cargo vehicle it does appear GWH used a prototype to base their original mouldings on. Although Bronco added extra features to many of the versions they later released, they did not update any of the main mouldings so many of the production vehicle features will need to be added.

These include the front bumper bar, the side vision ports; the wooden platform supports, the rear panel components on the chassis, the different front lights and the fuel filler cap.

The prototype bumper bars tapered in at the ends whilst the production series vehicles had simplified straight bars.

The two side vision ports on the kit are identical when in fact the production type drivers port was much larger.

The wooden platform supports appear to have changed through production although

photographic evidence in this area is thin on the ground. The prototype

version had the platform sitting higher than the production series but

how the wooden support structure changed in shape is unclear. Clear

images of the prototype vehicle support show clear daylight between them,

yet all the images of the production vehicles I can make out appear to

show a solid horizontal beam from front to back. That could just be a

trick of the light so it’s difficult to tell. The supports included in

the the kit, although of the prototype design, do thankfully sit at the lower

height of the production series.

Below is a wooden bodied cargo variant and it clearly shows that a solid wooden support seperates the bed from the chassis rails.

The chassis rear panel in the kit is of the prototype design. The production series had a step added to the offside. In addittion only one in four production sWS’s ever received a winch, but even when not fitted the holes in the rear panel still remained.

The image below is a wooden bodied sWS but clearly shows the production vehicle rear layout

The use of both Notek and Bosch headlights are seen in war time images.

The prototype fuel filler cap was simply screwed into the top of the

tank and was obviously difficult to fill under the platform bed so an

extended ‘S’ shaped funnel extending rearward can be seen on production

vehicles.

Very few war

time images exist of the interior on the armoured version, so areas of the cab

mouldings are still up for discussion. This kit does provide a split bulkhead

behind the driver on the sprue but oddly does not call it out for either

of the versions in this kit! It is used in their Flak variant kits.

Looking at images of the Flak variants it appears that a section of the cab roof was cut short at the rear to provide clearance for the Flak 43. The roof should end just behind the transverse strengthening bar. The area behind that is covered by a tarpaulin on a frame. I am not 100% sure if all the variants had the shortened roof, but on the Flak gun kits you are instructed to remove the access of the roof moulding. This kit does have witness marks on the underside of the roof and witness marks down the interior walls, however, the instructions in this kit only have you remove the witness marks!

Another

issue Great Wall Hobby made in this area, and one that Bronco did not remedy,

is the mistake of adding folded crew seats against the rear exterior walls of

the cab armour. What you are seeing in the image below are not seats but brackets

for rifles. The two black areas in the image on either side of the bulkhead are

holes to which rifles passed through. It is a mistake in the kit, and is clearly evident that any seat with a backrest inclined forward would not be practical.

The nuts-and-bolts CAD drawing below clearly shows the issue that the kit manufacturer misinterpreted. It also shows a small inward return

to the cab armour at the rear where it meets the load bed. This is not replicated in the kit.

The kit chassis is a one piece item

Front axle and suspension added

Sprockets and idlers I will be using

Front wheels fixed at full lock

Sandwhich design front wheels

Drivers side vision port (original plastic part)

Reworked passenger side vision port reduced in size

No front vision blocks are provide with the kit so you will have to source/make your own if displaying them open

Cab floor moulding

Production fuel filler cab extension made from stretched sprue

Cab floor, cab roof and loadbed test fitted to chassis

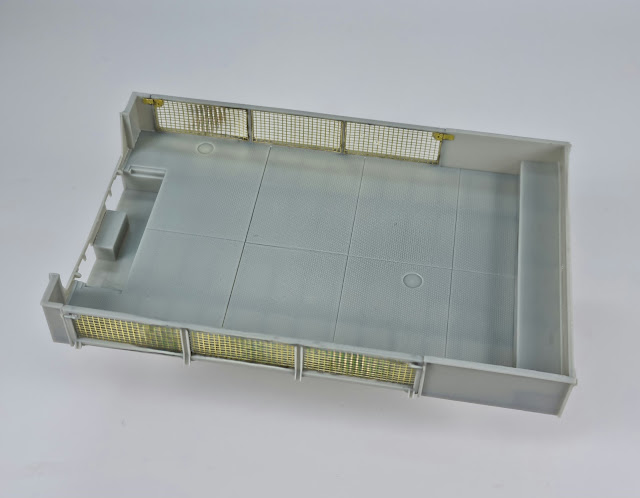

Loadbed assembly

Although I do not intend to beat up the paint finish on the exterior, there will have been prominent areas on the platform and side panels which will likely have seen some significant wear even over a short operating life. For this task, I will employ the ever-dependable hairspray method.

For this project I will be using MRP paints. These are lacquer based and require thinning and cleaning up with a lacquer thinner and not water. These are excellent paints that can be airbrushed direct from the bottle without the need for thinner if desired. I found for base coats my 0.4mm needle worked fine running between 10-12psi. You do need a few coats to build up the opacity, but what you are rewarded with is a lovely smooth and tough finish.

There is a

little confusion about whether MRP paints are suitable when utilising the

hairspray technique. I can categorically state they work absolutely fine. Obviously,

this is all dependant on the type and the amount of hairspray used and the type

and thickness of any overcoats laid down. There are plenty of tutorials on the

subject but personally I have always achieved good results with the Tresamme

fine mist cans of hairspray. I often decant and use via an airbrush for smaller

areas to be covered. Out of the can a couple of swift passes at arm’s length is all that is

required.

Chipping with MRP Paints

With MRP paints there is no need to protect any undercoat layers with varnish. It is tough enough to remain intact unless you really abuse it with sharp tools. Tamiya rattle can red oxide primer that I used is also extremely durable.

Chipping can begin as soon as the overcoat layer of paint is touch dry. I have found lukewarm water works better than cold in agitating the hairspray and the surface needs a little time to absorb any moisture. A drop of detergent can help to avoid any water pooling. Whereas even a soft brush or a cocktail stick is enough to scratch the surface on a Tamiya/water mixed overcoat, creating the same effects over this lacquer overcoat takes a little longer. Some modellers have even employed fibreglass pencils to start things off! However, if the ratios of hairspray and paint is in the sweet spot, extremely fine chips and scratches can be made without too much effort. Good results don’t happen overnight, so testing the method on a shelf queen or spare piece of plastic card will pay dividends.