Having recently finished building RFM’s Panzer IV Ausf J and currently still having lots of fun with their Panzer IV Ausf J interior kit, I really fancied tackling another one of their 1/35 armour kits. This year I’ve not started another soft skin, which is what I mainly build, as these kits have just been such a pleasurable experience. The engineering is so good, and the plastic such a similar colour match, that I keep thinking I’m building a Tamya kit😉

As the end of last year was all about Panzer IVs for me, this year I’m maxing out on StuG’s. Over the last few months, I have Dragon’s lovely StuG III Ausf F8 ready for paint. This will be based on an Italian campaign vehicle as I have some nice period images which capture some unusual features.

I also ‘blitzed’ through Takom’s StuG III Ausf G (Early). This was built straight out of the box with no intention of losing any sleep over its many inaccuracies.

So, as I’m slowly getting to know my way around a Panzer III chassis and many of the later StuG variants, I figured why not check out one of RFM’s StuG's. I choose their Ausf G late kit and it’s a belter. I’ve read there are a few small anomolies but they are minimal and nothing that cannot be easily remedied. According to those knowledgeable on ML, it is the perfect base kit that requires little extra work to portray a decent Alkett built last production Ausf G.

This is the non-interior 2022 released kit 5086 and you can build a StuG III or a StuH42. RFM 5086 info It includes both Alkett and MIAG track guards as it incorporates sprues from their Panzer III as well as from earlier StuG kits. The tracks are RFM’s own individual links which incorporates a jig to complete small runs, speeding up construction. There is no turned metal barrel, but the one-piece slide moulded one provided is easy to clean up. There are two frets of photoetch. The largest covers the Schurzen plates. The wheels incorporate poly caps which I personally like and fit nice and snug just like on many a Tamiya kit.

The lower hull is of flatpack design and fits together perfectly. The torsion bars can be made workable, or you can simply glue the ends onto the lower hull. There is even a choice to build adjustable shock absorbers. Your choice. When it comes to the bow armour the StuG III went through quite a few production design changes in this area. Unlike another certain manufacturer I could mention, the correct parts are called out, even though there are several other variant parts available on the sprues. The running gear lines up really nicely as does all the features on the rear plate.

The interlocking bow plate portion which would be partly visible just forward of each sprocket on each lower hull side, strangely isn't moulded on. I chiselled out the feature and added the welding marks. The transmission plate is just dry fitted in the image below.

One of the oddities in the kit, is the choice of tracks. The open guide horn type was seen on StuG III's, but the fitment was almost certainly not common. A period image that captured my attention had the more common type, seen on these variants, and as I had a 3D set of T-Rex links, I figured these were the ones to go for. That decision wasn’t one of my best! Unlike three earlier sets which I had a blast with, these were a right PITA. They definitely were not from the same batch as my earlier sets, as the material was far more brittle. I also had far too many links break! To compound the issue the top of the pins did not appear to show any taper, and a significant percentage were already damaged in their small bags! TBH, I thought of contacting the seller but figured, I should at least see if I can build up two complete runs first. I did, but only just, and the pins were falling out as quick as I popped them back in! In the end and after a selection of choice words, I brush painted over the link pin ends with Vallejo grey primer. This seemed to solve the issue, but I then found the links were a tight fit over the sprocket, and I now don't trust them to take much more handling!

After all the track building issues, I decided to give the kit tracks a go. Also, as RFM only offer the earlier style round tow cable clamps, I ordered the correct square Alkett type from Panzerwerk Design Alkett late tow cable brackets. Whilst postage is way in excess of their cost, I also plumped for some of their Type 6B tracks Pz.III & IV type 6B links at the same time. They look good and have favourable reviews, so I will build them up when they come, and choose whether they trump the kit tracks later in the build.

As it would give the choice to display the vehicle on uneven ground, I opted to utilise the kit's adjustable torsion bar set up, which work in conjunction with the kit’s optional moveable damper units. Due to the kit's engineering in this area this system naturally allows the wheels to lift over any obstacle beneath them, and the moveable damper units equally compress, but the design does not enable the torsion bars to naturally rebound. This effect is visible in the first image below. The first and last front bogie wheels are slightly affected unnaturally by the kit track tension and are pulled a little higher than they would normally sit on level ground. It’s not really an issue per say, and if displayed on even ground the final position can still be corrected, so it’s nice to have this option.

The T-Rex tracks do look the business, but this set was far from perfect. The track tension on the other side is a touch loser on the image below, so all the bogie wheels sit nice and level.

One construction fix which was pointed out to me by a fellow modeller, involves two strengthening ribs (parts D13 & D14), which you are instructed to add to the undersides of the gun box in step 13. What they do in essence, is create a channel which allows the gun box to align squarely onto both of the thin lower hull side plates. The problem is that they only need to be fixed a fraction off and the channel will become too narrow. To remedy this potential fit issue, you just need to attach the parts directly to the lower hull instead. There are alignment slots in the lower hull side plates too, so it’s a really simple fix.

The lower hull interior includes a fighting compartment floor to which the gun cradle fixing mount is attached. At the rear only the inner two of the four spars that you are instructed to fit between the lower hull back plate to the extension over the exhausts featured on these late production vehicles. It is not an issue to fit them as instructed as they are not visible (unless you are an IPMS/USA judge) and the extension rear plate outer detail has the correct bolt head detail for just the two inner ones that remained.

In step 15 you get to choose your gun type and unlike any earlier manufacturer's releases, each gets its own parts and construction steps. It is worth mentioning that in step 19 it is not at all clear in which order to attach the breech sub-assembly, gun box, lower hull and mantlet all together! I’m sure there are a few ways that folks have managed to do this successfully, but it is not at all obvious and quite a conundrum to figure out.

Breech assembly with added weld detail on the

recuperator and an aftermarket barrel. I incorporated the kit's spring so I can

leave it adjustable to ensure I end up with the correct length of visible

barrel outside of the mantlet.

The full breech sub-assembly with the mantlet and

muzzle brake dry fitted.

I’m currently building up the engine deck which comes as a separate moulding but I’m not going to attach all the parts permanently until I can confirm how the Legends Production stowage I have sourced is contoured to fit.

Engine deck, armoured engine hatches and gun box roof still dry fitted.

The loaders front armour plate provided in the kit is of the earlier production design which incorporated two (50 & 30mm) plates. Late Ausf G had a single 80mm plate. It would be quite easy to hide the join if it were not for the fact that the kit’s outer 30mm plate part does not feature the extra portion that curves down to match the contours of the inner plate. I shaped a similar thickness piece of grey styrene to mimic the outer plate then scribed torch marks over both plates to hide the join. I understand the correct single 80mm plate can be found spare on the sprues of many a Dragon StuG kit.

RFM appear to have used the same gun box moulding as in their early Ausf G kit, so some features require alteration. The instructions do point out the removal of witness marks for the smoke dischargers, and the removal of four rivets on both sides, to enable the fitment of the Schurzen hangers. They don’t however instruct you to fill the four small holes on the rear. These were to enable fitment of the earlier production rear loaders hatch which was re-designed.

Moving onto the engine deck moulding, this fits perfectly onto both the lower hull and against the back of the gun box, and if you wish, can be fixed in place before any further accessories are added. If like me, you prefer to add the most fragile items once the large assemblies are in place, access to all the added parts shown in steps 25 to 27 remain unhindered if you do.

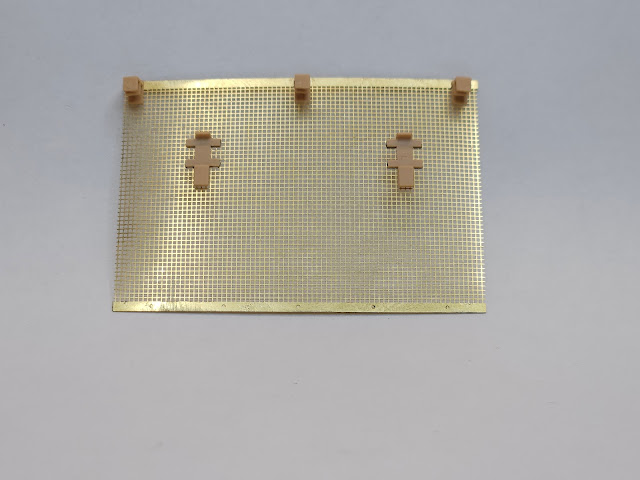

All the engine hatches come as separate items. Yet another oddity with the instruction sheet is that a small 3D part is to be added just behind the cleaning rods on the rear deck, yet there isn’t one in the kit, nor is it shown in the included parts map! Very odd, as the part shape is both difficult to identify should you wish to scratch a replica, and you are left with a small locating hole on the deck! A more important possible anomaly is the inclusion of diagonally shaped mesh for the engine cooling louvres. Although not conclusively proven it is believed that Alkett produced late Ausf G vehicles were only seen with a square mesh type. Late MIAG vehicles look to have retained the diagonal type, but to muddy the waters further an unmolested museum piece has a combination of both! I don’t think using the kits photo-etched item would be a massive issue, but the square type is available from two aftermarket manufacturers. The kit also includes a multipart photoetch support rail which fits around the outside of the engine deck. As period images showed these vehicles crammed with added stowage and crew gear, I plan to add some aftermarket stowage so that will be tackled at the same time to ensure it all fits together nicely.

As we have seen already, there are a few features that were unique to one or the other of two manufacturers that built the final batch of Ausf G, but unlike MINIART, RFM do not specify which one they are representing. Most features you are instructed to add, do point to an Alkett built vehicle; however, a few others have been confused. If you know what features are particular to each manufacturer then it makes it easier to differentiate, and the inclusion in the kit of almost all the features of both, is a big plus. If depicting an Alkett build, it is worth noting that RFM only include the original round type MIAG installed tow cable brackets. Alkett brackets were a unique square shape and as the kit part is moulded to the tow hooks, they ideally will need to be replaced along with aftermarket copper braided tow cables. Both Modelkasten and Panzerwerk design offer these brackets. Observing the details on the Alkett track guards; the tubular supports are not quite as faithfully represented as they could be. The shape is not quite on the money, but inclusion of photoetch strengthening ribs improve the overall appearance. The rear convoy light RFM provide is not one that either manufacturer fitted. It should be of the tube type design. These can be found as spares in many Panzer kits. I believe RFM’s own Panther have them.

As

in their earlier Panzer III and IV kits, RFM have moulded the main part of all the

tool brackets to the tools, but the clasps come as photoetch parts. It’s a neat

way of keeping the photoetch parts count down, whilst also enhancing the scale

appearance of the most prominent feature of the bracket. The inclusion of

separate tow clevis brackets in photoetch is also a welcome addition. It is

just a single piece but does require careful bending before fixing in place. The clasp is yet to be added in the image below.

As already mentioned, test fitting both the gun breech assembly and the mantlet to the gun box is a tricky affair, but the fitment of part G65 pretty much insures they have to be fixed in place at this point. I wanted to paint the interior, and fixing part G65 as instructed will essentially trap the breech assembly inside, or if not paying attention, outside! A simple fix is to add part G65 to the roof plate (part G110) instead, leaving the roof plate the last part of the gun box to be fixed in place. I sourced a kit specific aftermarket metal barrel, and along with the spring, fixed it to the breech assembly leaving it moveable, so I could paint the whole sub-assembly separately.

The

rotating cupola can be built with the small periscope flap open or closed, and

if you wish to keep the cupola separate to paint, the clear part vision blocks

can easily be fixed in place after paint. The kit also includes a finely

detailed but delicate photoetch engine hatch retaining bracket which connects

to the rear wall. The remote-controlled gun mount is easily built up but there

are question marks as to whether the shields are of the right shape. Rado

miniatures have just release a 3D set should you wish to go all in. As already

mentioned, my roof will remain separate until the interior is painted and the

breech and mantlet slotted into place. Radio aerials will be added as a very

last step to avoid damage.

Progress before all but the smallest and most fragile parts are added. Tamiya rubber band tracks have been added just to keep all the wheels in line for the pic.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)